Fully automatic cavity preservation in automotive production

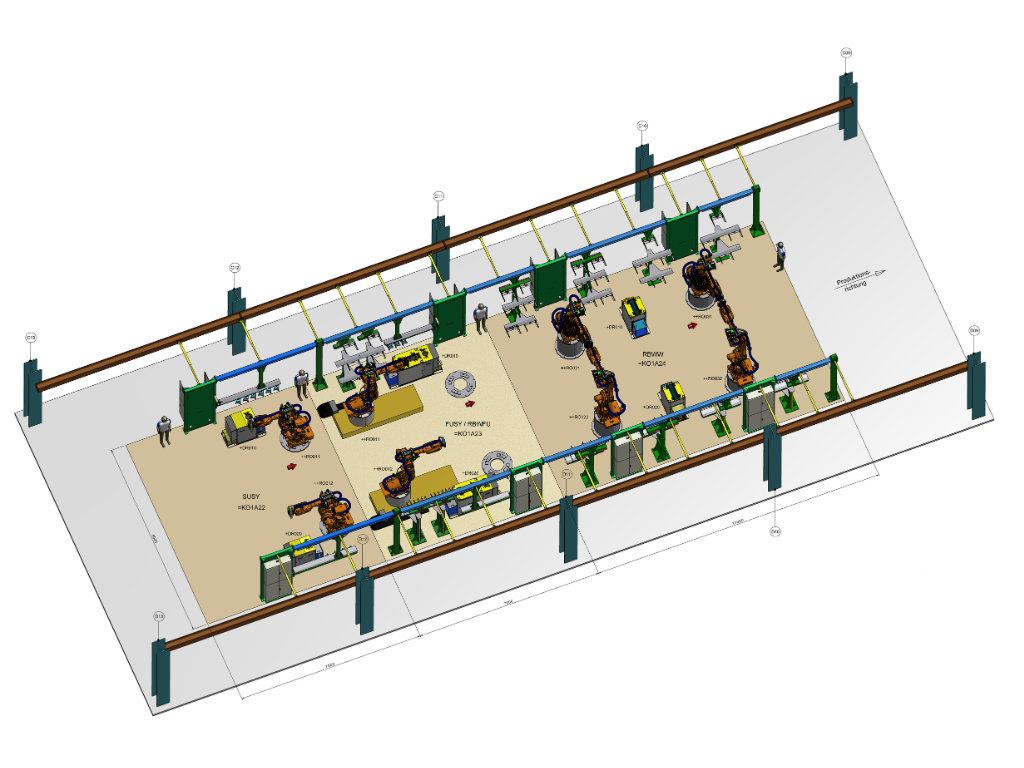

SAR has designed and implemented a line for fully automatic cavity preservation for BMW AG in Munich. The line conveys car bodies via the first workstations for the installation of operating fluids, via systems for foaming and door preservation to the first of 3 stations for cavity preservation.

3 stations for cavity preservation

From the 3 stations “SUSY”, “FUSY” and “RBWW”, the last unsealed cavities in the body are preserved fully automatically.

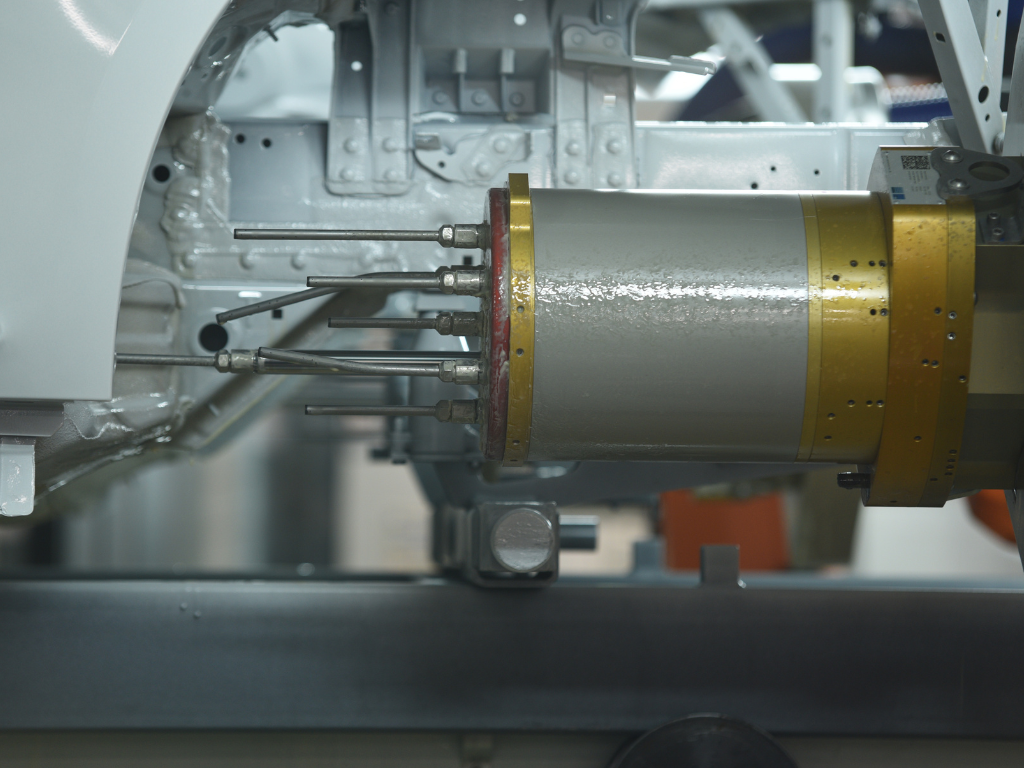

Different application heads are used for this:

- RBWW: Robot beam with two cheeks each

- SUSY: 7-fold application head

- FUSY: 4-fold application head

- RBWFU: Robot beam with two cheeks each FUSY-compatible

All application heads are equipped with a robot coupling on the tool side so that they can be deposited either in the racking or cleaning stations.

Station 3 “SUSY” – Seven Up System

Cell section 3 of the overall “cavity preservation automation” system covers the hard-to-access application area of the car body.

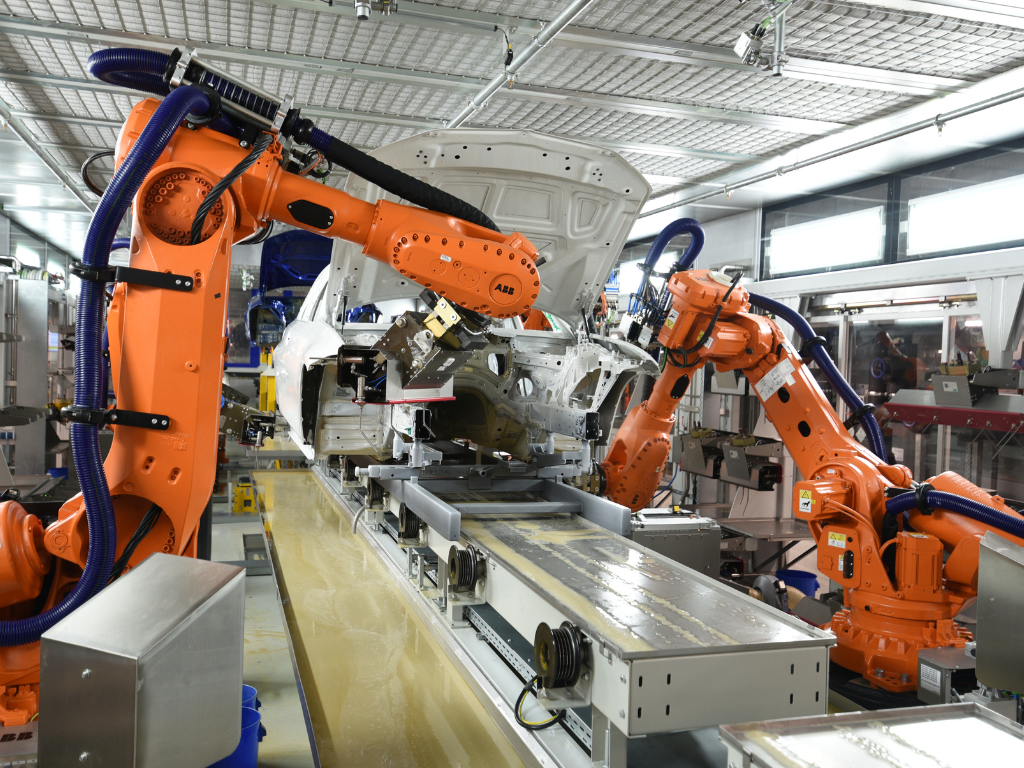

It consists of two stationary robots with a maximum of twelve 7-fold application heads (SUSY) equipped with applicators and nozzles, two dosing cabinets, two nozzle cleaning stations (DRS) and two storage racks for the SUSYs.

Station 4 “FUSY” – Four Up System

In cell section 4, the body is raised by means of a lifting table, covering all application areas in the underbody.

It consists of 2 robots on the 7th axis with a maximum of 14 robot beams, two cheeks each (RBWFU) and four 4-fold application heads (FUSY) equipped with applicators and nozzles, two nozzle cleaning stations (DRS) and four storage racks for the RBWFUs and FUSYs.

Station 5 “RBWW” – Robot, beam, cheek, cheek

In cell section 5, the sills, engine mounts and hood of the body are covered, among other things.

It consists of 4 stationary robots with a maximum of 40 robot beams, each with two cheeks (RBWW), which are equipped with applicators and nozzles, as well as two centrally arranged nozzle cleaning stations (DRS) and four storage racks for the 40 RBWW tools.

Maintenance scales are available for all 3 stations in order to exchange application heads for maintenance purposes.

Backup solution

In the past, the workers had to apply the individual punctures in the bodies by hand.

This is now only intended as a backup solution in case the system reports a nozzle problem or a robot failure, for example.

In this case, there are 2 rework stations after the robot cells, where any problem cases are automatically stopped.

The necessary rework is clearly displayed to the worker.

Successful in use – interesting for the USA

The Munich plant has been successfully in operation for some time and the “FUSY” station is being set up and put into operation 1:1 at BMW USA in Greer.

For further information please contact us at ofs@sar.biz