SAR dosing technology in use at MINI

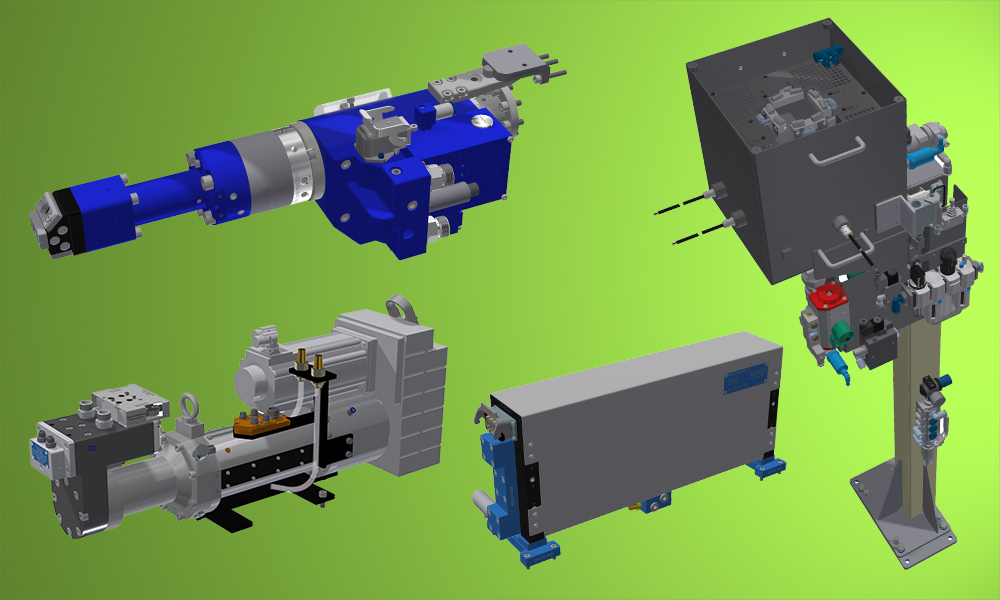

Dosing units, water-cooled Peltiers, cleaning stations and guns designed by SAR were and are installed in the pre-assembly in Dingolfing and integrated on site in Oxford in the shortest possible time, including robot programming.

Offline simulation using a DOP (Deep Optimistic Planning) system enabled the robot programs to be adapted during operation.

Other upgrades included the “paint material supply” with 17 new paint systems and the “PVC from top” upgrade with our water-cooled Peltiers.

The switch from MINI IPP (Integrated Paint Process) to BMW IPP will keep us busy until 2021, with the renewal of all paint ring lines, supply groups and the control system.

SAR was or is the general contractor for all projects.

MINI sees its investment in the paint shop confirmed by demonstrably improved quality and lower material consumption.

The company newspaper reports that the new 3D gun heads allow better access to the underbody of the body, increasing quality and accessibility.

MINI has met and even exceeded the expectations of its specifications.

If we have aroused your interest in SAR’s dispensing components with these references, please write to us at ofs@sar.biz