This cell shows how production processes can be controlled in an energy-efficient manner, how component information can be tracked for life and how simple error visualisation can be ensured throughout the entire production process.

TIA Portal forms the control basis.

Existing standards have been expanded to include process technology applications for the solution.

If you have any questions or require further information, please contact us at kss@sar.biz.

AUTOMATION IN THE PLASTICS INDUSTRY

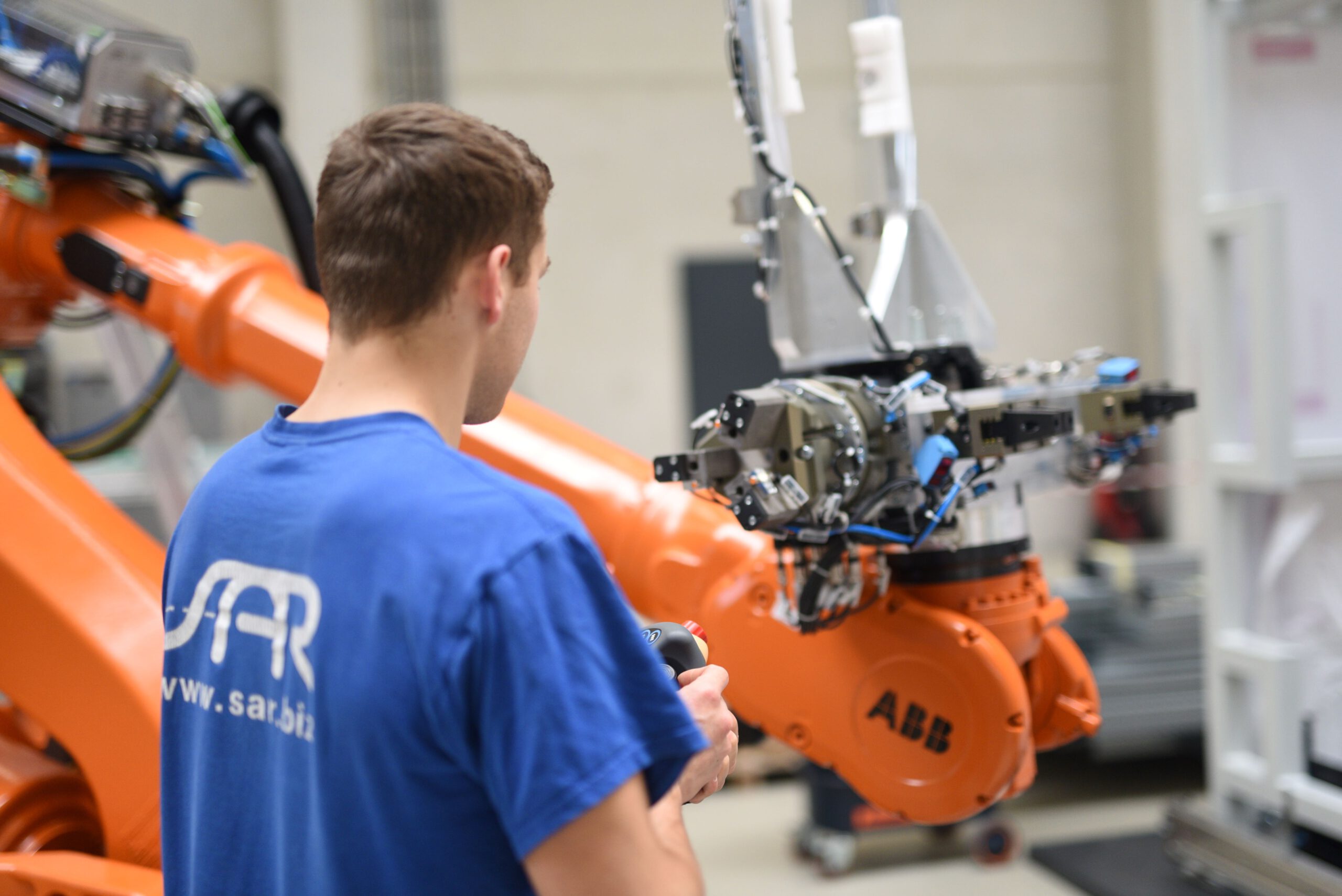

SAR Gunzenhausen is one of the world’s largest independent automation companies in the plastics sector and offers customised solutions based on the SAR modular automation system.

For our customers, this means that they can operate and control a wide variety of injection moulding and plastics machines as well as different robot systems with a uniform, cross-system user interface. Click here to go to our service portal for plastic systems: www.sar.biz/service(instructions / documentation).

- INJECTION MOULDING AUTOMATION

- BLOW MOULDING PROCESSES

- CLEANROOM APPLICATIONS

- ASSEMBLY AUTOMATION

- SPECIAL APPLICATIONS

- ROBOT INTERLINKING

- MACHINING AND PRODUCTION CELLS

DIGITISATION

From the digital twin, to the “fast error detection” software, to the specially configured MES system for the plastics industry, SAR Kunststoffsysteme offers all the technologies for a successful implementation of “Industry 4.0”.

Seize the opportunities of digital transformation and shape the future of production in a more efficient, networked and innovative way!

Compact automation solutions and customised gripper technologies are another hallmark of SAR Kunststoffsysteme, which now has over 1,500 robot solutions installed worldwide.

Together we are shaping the future of automation – innovative, reliable and powerful.

REFERENCES

PRO

JEC

TS

PRO

JEC

TS

BRO

CHU

RES