Pacesetter for electromobility

Although e-mobility has long been a topic in the automotive industry, it is still a relatively new business area.

Accordingly, new opportunities for automation need to be discovered.

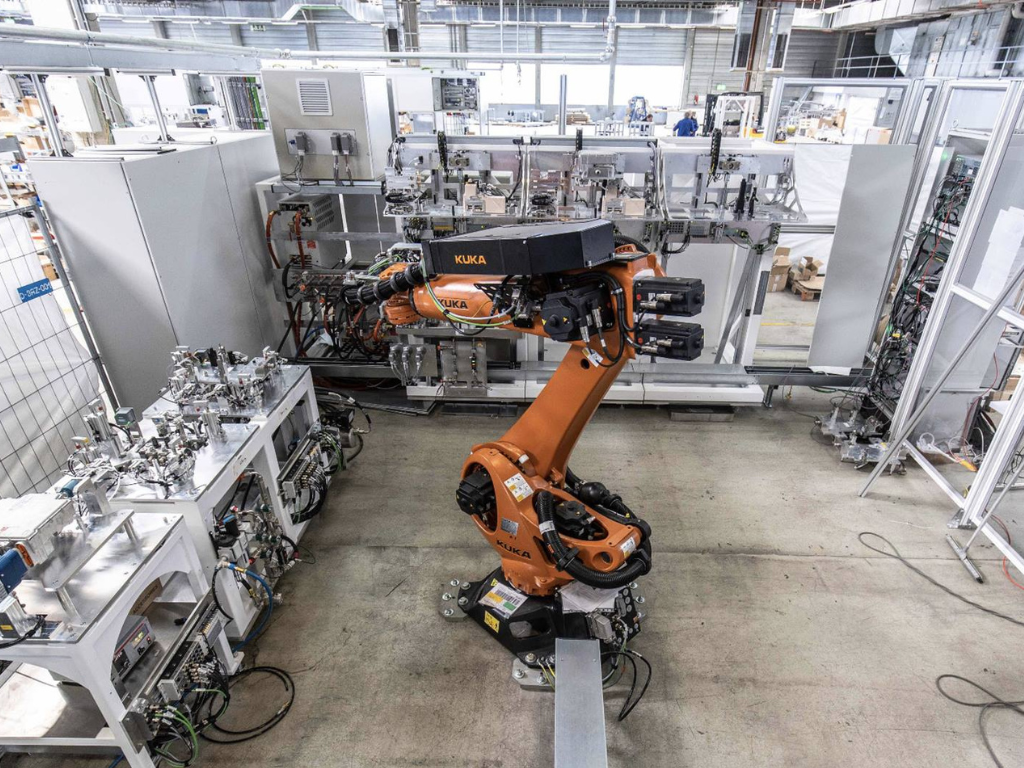

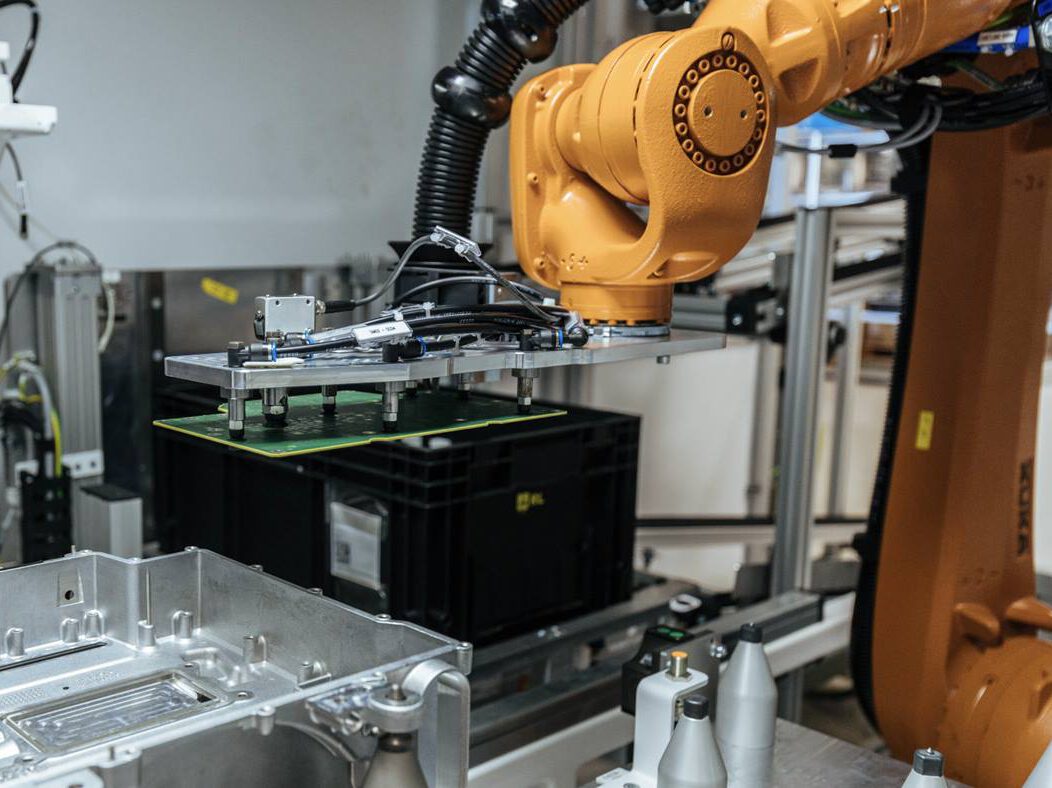

With the help of 11 KUKA robots and 17 HIRATA screwdriving robots, SAR has developed a fully automated, scalable production line for the heart of electric cars.

The heart of an electric car

The electronics module.

An inconspicuous device with enormous importance.

As the central control element in the vehicle, it converts the direct current from the batteries into alternating current.

Only then does the engine convert the emission-free energy into power.

Due to the new technology, suitable concepts for the intelligent production of electric cars and integration into the production process are in great demand.

In collaboration with KUKA and its robots, SAR has developed an automated production process that not only assembles assembly parts for electric cars, but also controls and monitors all process steps, from marking the individual parts, to screwing and gluing tasks, to testing and checking the intermediate steps and ultimately the finished product.

This production concept was implemented at three locations (Erlangen, Vezprem in Hungary and Shanghai in China) in a total of five lines for two car manufacturers.

Automation at the highest level

All relevant automation tasks in the configuration of the production line are performed by 28 robots – 11 of which are from KUKA.

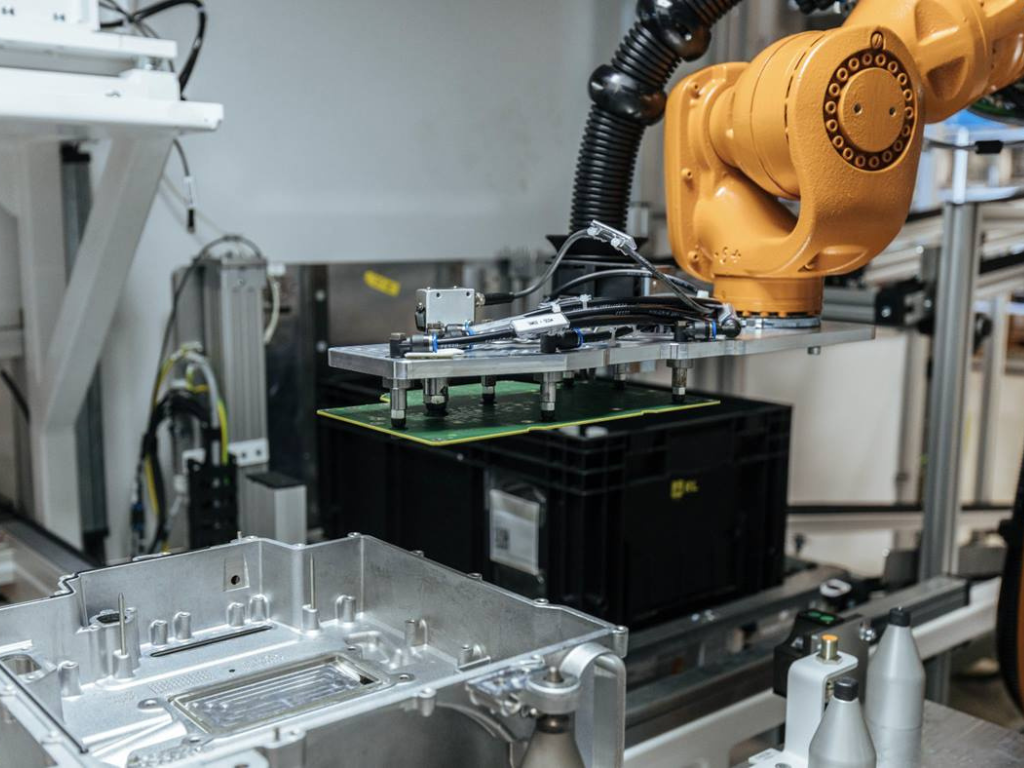

The industrial robots insert various electronic components into the housing of the control unit.

They clean and inspect, sort out or rework.

Each assembly step is carried out carefully and precisely, as the components are as sensitive as they are necessary for the finished electric car.

Production takes place under EMC and clean room conditions.

This means that bonding points are first cleaned and dirt particles are removed during the production process.

Robots then apply sealing compound and the various components are inserted into the housing.

Robots then screw the components together.

The screws are first separated from the dust using compressed air.

Leak tests and functional tests are carried out repeatedly in between to ensure the high quality of the workmanship.

In the final step, the finished control units are removed from the conveyor belt by a robot and filled with water.

The water is used for cooling during the subsequent test steps.

A KUKA robot places the control units in the high- and low-voltage insulation test.

They are then given their operating system by flashing the inverters.

Once all the tests have been passed and the water drained, the control units are ready for their life as pacemakers in an electric car.

Scalable solution, individually customizable

The solution is highly scalable and customizable: with the help of driverless transport systems, the various electronic components could already be collected from a so-called supermarket and brought to the stations.

It would be possible, for example, to set up the production line in different stages, parts of which could even be used by suppliers.

The desired degree of automation depends entirely on the customer.

For more information, please contact us at aut@sar.biz.